Mục Lục

- 1. Why Choose Aluminum CNC Cutting?

- 2. Aluminum CNC Cutting Units in Dong Nai

- 3. CNC Aluminum Cutting Process According to Request

- 4. Benefits of Using Aluminum CNC Cutting Services in Dong Nai

- 4.1. Save Time and Cost

- 4.2. High Quality Products

- 4.3. Attentive Customer Service

- 4.4. Technical Consulting Capability

- 4.5. Flexibility and Responsiveness to Market Demand

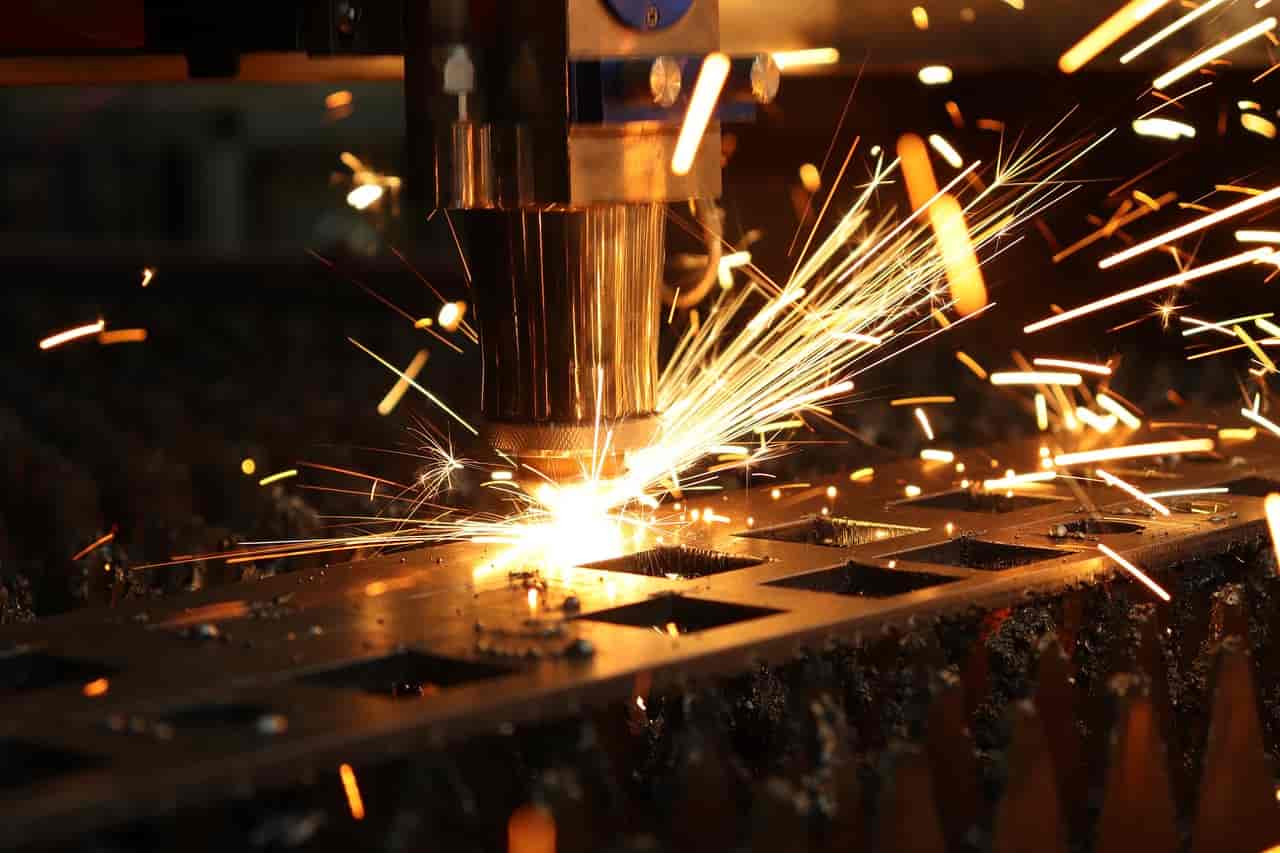

In today’s industrialization context, the demand for aluminum materials in production and manufacturing is increasing. Aluminum is not only light and durable, but also has good corrosion resistance, making it an ideal material for many applications. With the development of CNC aluminum cutting technology (Computer Numerical Control Cutting), the production of aluminum products on demand has become easier and more efficient than ever, especially in developed provinces such as Dong Nai.

1. Why Choose Aluminum CNC Cutting?

1.1. High Precision

Aluminum CNC cutting stands out with its outstanding precision, which is a key factor in helping products meet high technical standards. This technology allows the creation of complex details accurately, repeatedly without any errors. This not only improves product quality but also minimizes risks in the production process, ensuring that each product meets the most stringent requirements from customers.

1.2. Optimizing Production Costs

Although the initial investment in CNC cutting machinery can be relatively high, the economic benefits it brings in the long term are significant. This technology saves production time and minimizes excess material, thereby reducing overall costs for businesses. Thanks to the ability to optimize the process, companies can increase profits and minimize waste, contributing to sustainable development.

1.3. Flexibility in Design

One of the outstanding advantages of CNC cutting technology is the flexibility in product design. Businesses can easily adjust the size and shape of the product without making many changes to the production process. This is extremely useful for businesses with diverse production needs, helping them quickly adapt to the market and customer needs.

1.4. Mass Production Capability

CNC cutting technology not only helps to produce customized aluminum products quickly, but also allows businesses to mass produce with high efficiency. This not only enhances competitiveness in the market but also helps companies to meet customer needs in a timely manner, thereby expanding production scale and maximizing profits.

2. Aluminum CNC Cutting Units in Dong Nai

2.1. Advantages of CNC Cutting Facilities in Dong Nai

Dong Nai stands out as one of the leading industrial development provinces in Vietnam, with a series of concentrated industrial parks. The presence of many aluminum CNC cutting units here not only creates great opportunities for businesses but also brings many significant advantages:

- Geographical Proximity: Locating CNC cutting facilities in the Dong Nai area helps businesses save on transportation costs and minimize delivery times. This is extremely important in the current competitive context, where time and cost are always decisive factors.

- Highly Skilled Technicians: CNC cutting units in Dong Nai often have a team of experienced and highly skilled technicians. This ensures that the products not only meet quality standards but also reflect sophistication in design and manufacturing.

- Modern Equipment: With investment in advanced machinery, CNC cutting facilities in Dong Nai are capable of meeting the diverse aluminum cutting needs of customers. Modern technology helps increase work efficiency and minimize errors in the production process.

2.2. Some Typical Aluminum CNC Cutting Units in Dong Nai

As one of the leading units in the field of aluminum CNC cutting, Dong Phuong Furniture Production and Trading Company Limited specializes in providing services with modern production lines. The company is committed to providing high quality products, strictly inspected and ensuring on-time delivery. With a team of experienced technicians, they are always ready to meet all customer requirements, from small to large orders.

- Dong Nai Aluminum Production and Trading Company Limited

Dong Nai Aluminum Production and Trading Company Limited is a familiar name in the aluminum manufacturing industry in the region. With many years of experience, the company not only provides aluminum cutting services on demand but also ensures product quality through the use of modern machinery and advanced technology. The company’s technical team always strives to bring the best solutions to customers.

- Duc Thinh Mechanical Processing Joint Stock Company

Duc Thinh Mechanical Processing Joint Stock Company specializes in the field of precision mechanical processing, especially CNC aluminum cutting. This unit is capable of handling orders from small to large, quickly and effectively meeting the needs of customers. With modern equipment and professional working processes, Duc Thinh is a reliable choice for businesses in need of quality CNC aluminum cutting services.

3. CNC Aluminum Cutting Process According to Request

3.1. Receiving Request

The CNC aluminum cutting process begins when the customer sends the cutting unit the design drawings or detailed information about the product to be manufactured. At this stage, the technical team will carefully review the requirements and advise on the implementation capabilities based on existing technology and equipment. Receiving the request is not simply recording information, but also an opportunity to exchange and clarify the necessary details, to ensure that the final product will meet the customer’s expectations.

3.2. Consulting and Design

After receiving the request, the technician will proceed to optimize the design based on the drawings and information from the customer. This process includes adjusting factors such as distance, size, and ratio to best suit CNC cutting technology. The main goal is to ensure that the design is not only feasible but also optimal in terms of materials and cutting time. During this stage, the creativity and expertise of the engineering team will play a significant role in creating high-quality products.

3.3. CNC Machine Programming

Once the design has been approved, the next step is to program the CNC machine. The engineer will input the necessary parameters into the machine’s control system, including length, thickness, and other specifications. This stage requires absolute precision, as any errors can affect the quality of the final product. The engineer will also set up cutting commands, ensuring that the machine will operate efficiently and safely.

3.4. CNC Cutting Process

Once the programming is complete, the CNC cutting machine will begin the aluminum cutting process according to the set commands. This process is automated with a very high level of precision, thanks to the use of advanced technology. Technicians will constantly monitor to ensure that everything goes smoothly and without any problems. This not only helps to optimize the production process but also ensures that the product always meets the highest quality standards.

3.5. Quality Control

Once the cutting process is complete, the product will be put into the quality control stage. This is an important step to ensure that the product fully meets the standards required by the customer. The inspection team will measure the dimensions, evaluate the surface finish, and check other factors such as durability and accuracy. This inspection not only helps to detect potential errors early but also creates confidence for the customer in the quality of the final product.

3.6. Delivery

Finally, the product will be carefully packaged and prepared for delivery. The packaging is not only to protect the product during transportation but also to demonstrate the professionalism of the CNC cutting unit. The product will be delivered to the customer on time, ensuring that the customer can receive their product quickly and conveniently. This process not only concludes a production cycle but also opens up opportunities for a long-term cooperative relationship between the customer and the service provider.

4. Benefits of Using Aluminum CNC Cutting Services in Dong Nai

4.1. Save Time and Cost

One of the biggest benefits of using CNC aluminum cutting services in Dong Nai is the ability to save significantly on time and cost. With an optimized production process, CNC cutting units here can execute orders quickly while still ensuring quality. The favorable geographical location also plays an important role, helping to reduce transportation costs and delivery times, thereby improving the business performance of enterprises. Saving time in the production process not only helps enterprises provide products to customers on time but also creates opportunities to expand scale and increase revenue.

4.2. High Quality Products

CNC aluminum cutting units in Dong Nai are all committed to providing high quality products, meeting the most stringent requirements from customers. With modern CNC cutting technology, aluminum parts are manufactured with almost absolute precision, helping to minimize errors and improve product quality. Moreover, the strict quality control process after production ensures that each product meets standards before reaching customers. This not only helps businesses build reputation but also creates trust and satisfaction from customers.

4.3. Attentive Customer Service

An indispensable factor in choosing a CNC cutting service provider is the quality of customer service. At units in Dong Nai, the staff is always ready to support and enthusiastically advise customers throughout the working process. The friendliness and professionalism of this team not only creates a sense of comfort for customers but also helps to quickly resolve questions and requests, thereby improving the customer experience. Attentiveness in customer service is also demonstrated through tracking order progress and promptly notifying customers of any changes.

4.4. Technical Consulting Capability

CNC cutting units in Dong Nai do not stop at providing aluminum cutting services but also have the ability to provide in-depth technical consulting. A team of experienced technicians will support customers in optimizing design and production processes. They can give useful suggestions to improve production efficiency, helping customers save costs and time. This advice is especially important in large projects or products with complex technical requirements, where design adjustments can greatly affect the final result.

4.5. Flexibility and Responsiveness to Market Demand

Today’s market requires flexibility and the ability to quickly adapt to changes. Aluminum CNC cutting units in Dong Nai are capable of quickly responding to diverse customer requirements, from large-scale production to small orders, or customized products according to specific requirements. This flexibility not only helps businesses adapt to the market easily but also creates opportunities for development and expansion of production scale.