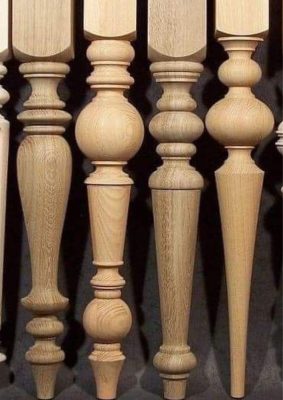

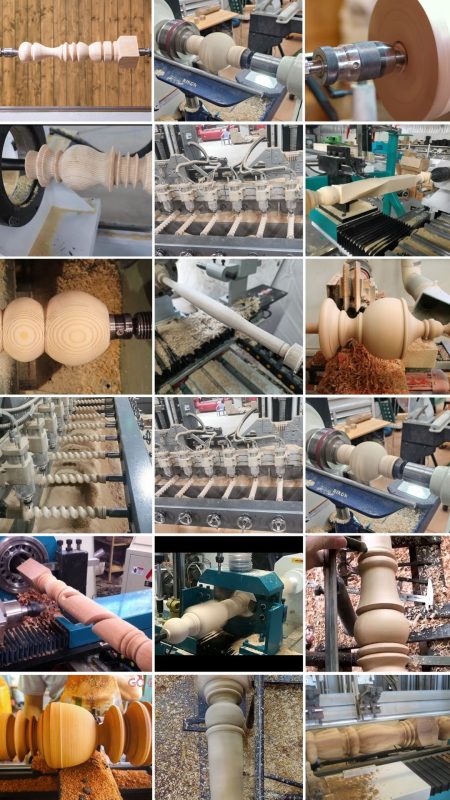

WOOD TURNING

- Fast processing of complex details in a short time

- Saving raw materials during processing

- Consistent products, high quality, aesthetics and finishing

- High precision and finishing of products

- Can use many types of wood

Advise: 0856.186.999

Email: giacongdpf@gmail.com

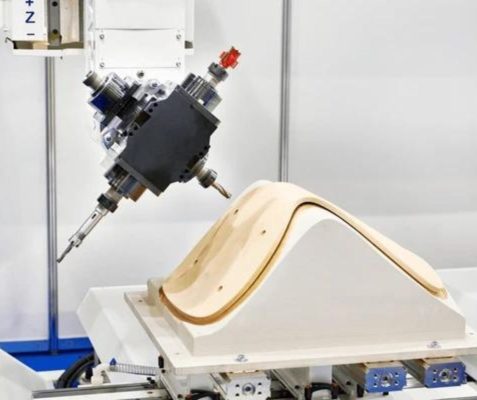

CNC Wood Turning on Demand

Dong Phuong Furniture Company is a reliable address specializing in providing CNC wood turning services in Dong Nai. With a team of skilled and experienced experts, the company is committed to providing high quality products, meeting the maximum requirements of customers.

Dong Phuong Furniture invests in modern equipment and technology, helping the production process to be efficient, fast and accurate. The company is capable of processing a variety of wooden products, from details of home furniture such as tables, chairs, cabinets, beds to wooden products such as cutting boards, turning wood to meet both mass demand and custom orders. With competitive prices, Dong Phuong Furniture always seeks to optimize the production process to provide products at reasonable costs.

In particular, the company provides custom design services according to customers’ ideas and requirements, along with quality after-sales service, ensuring customer satisfaction. With professional advice on design and interior trends, Dong Phuong Furniture is always committed to completing on time, meeting the needs of businesses and large projects.

Ordering Process At Dong Phuong Furniture

1. Receiving requests

- Customers provide ideas, drawings or detailed descriptions of the desired product.

- Staff will discuss to understand the requirements and expectations of customers.

2. Design consultation

- The team of experts will advise on product design, materials, colors and finishing.

- Provide information on modern design trends and features of each type of material.

3. Design sketches

- Based on the requirements and consultation, the company will create initial design sketches.

- Customers will review and comment on these sketches.

4. Editing and finalizing the design

- After receiving feedback from customers, the design team will make necessary edits.

- This process can be repeated several times until the customer is satisfied with the final design.

5. Design confirmation

- Once the design is completed, the customer will confirm and sign the contract.

- Information on price, delivery time and other terms will be clearly defined.

6. Production

- The company starts the production process according to the approved design.

- Using modern technology to ensure high quality and accuracy.

7. Quality control

- The products will be thoroughly quality checked before delivery.

- Ensure that the products meet the standards required by the customer.

8. Delivery

- The products will be delivered to the customer on time as committed.

The company will also support the customer during the installation process if necessary.

9. After-sales service

- After delivery, the company will contact to ensure that the customer is satisfied with the product.

- Support to handle any problems that may arise.

Sample product:

OTHER SERVICES