2D CNC SERVICES

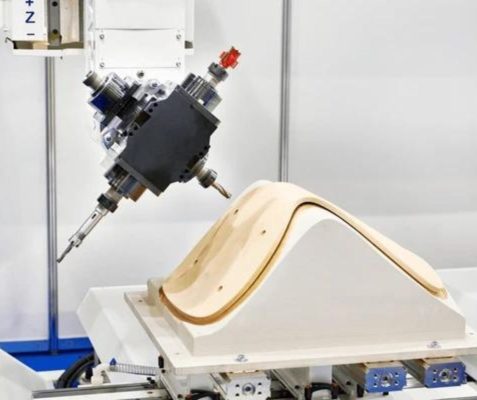

- High precision in size and shape

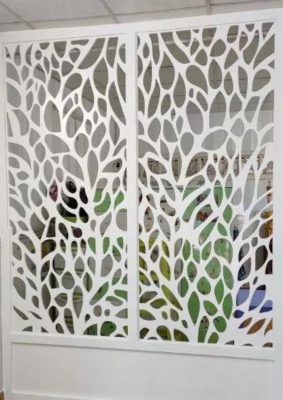

- Can cut difficult and complex details

- High-speed, high-volume production

- Can use many types of wood

Phone: 0856.186.999

Email: giacongdpf@gmail.com

Address: Group 2, Ap Vam, Thien Tan, Vinh Cuu, Dong Nai, Viet Nam

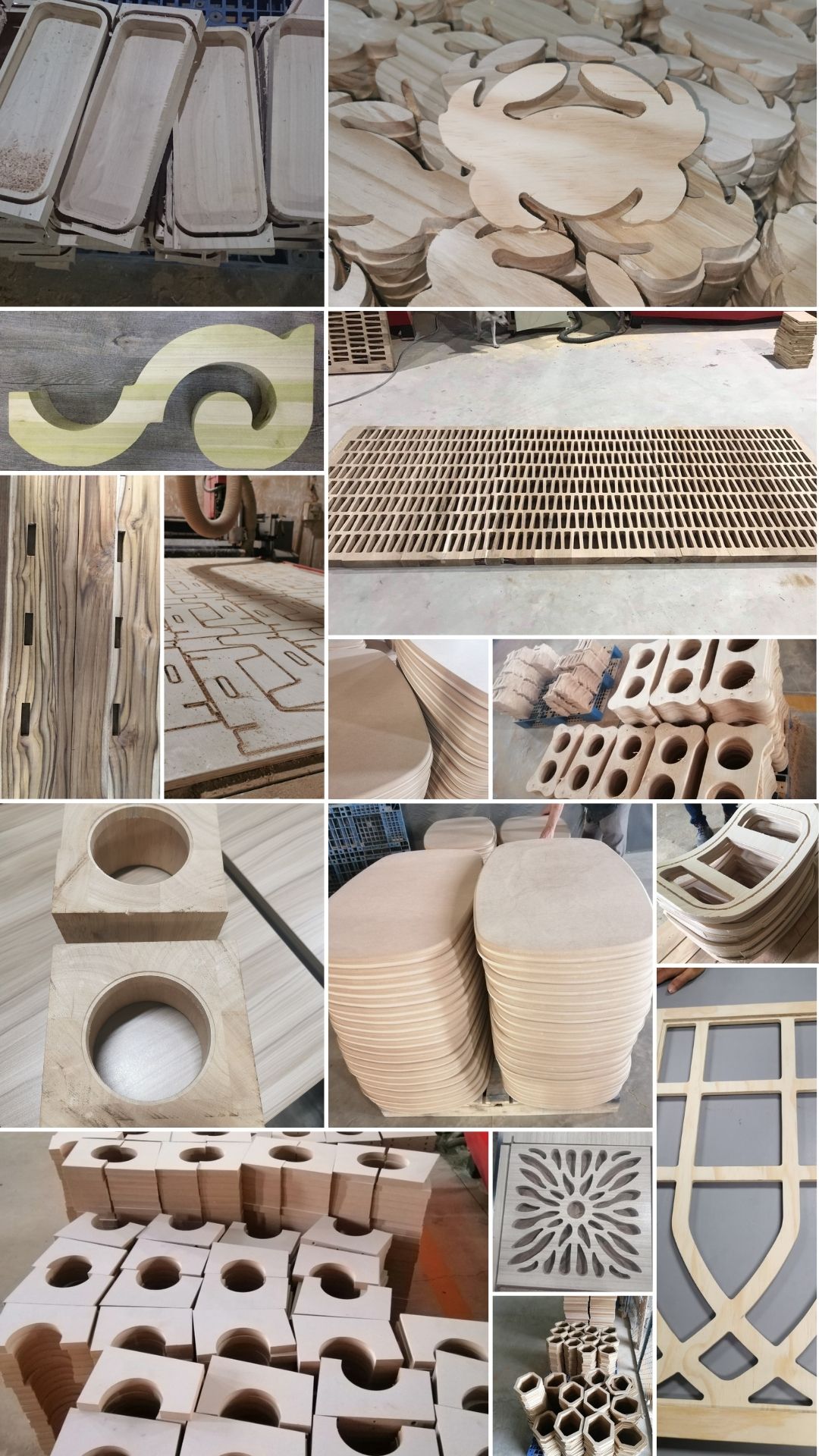

2D CNC MACHINING

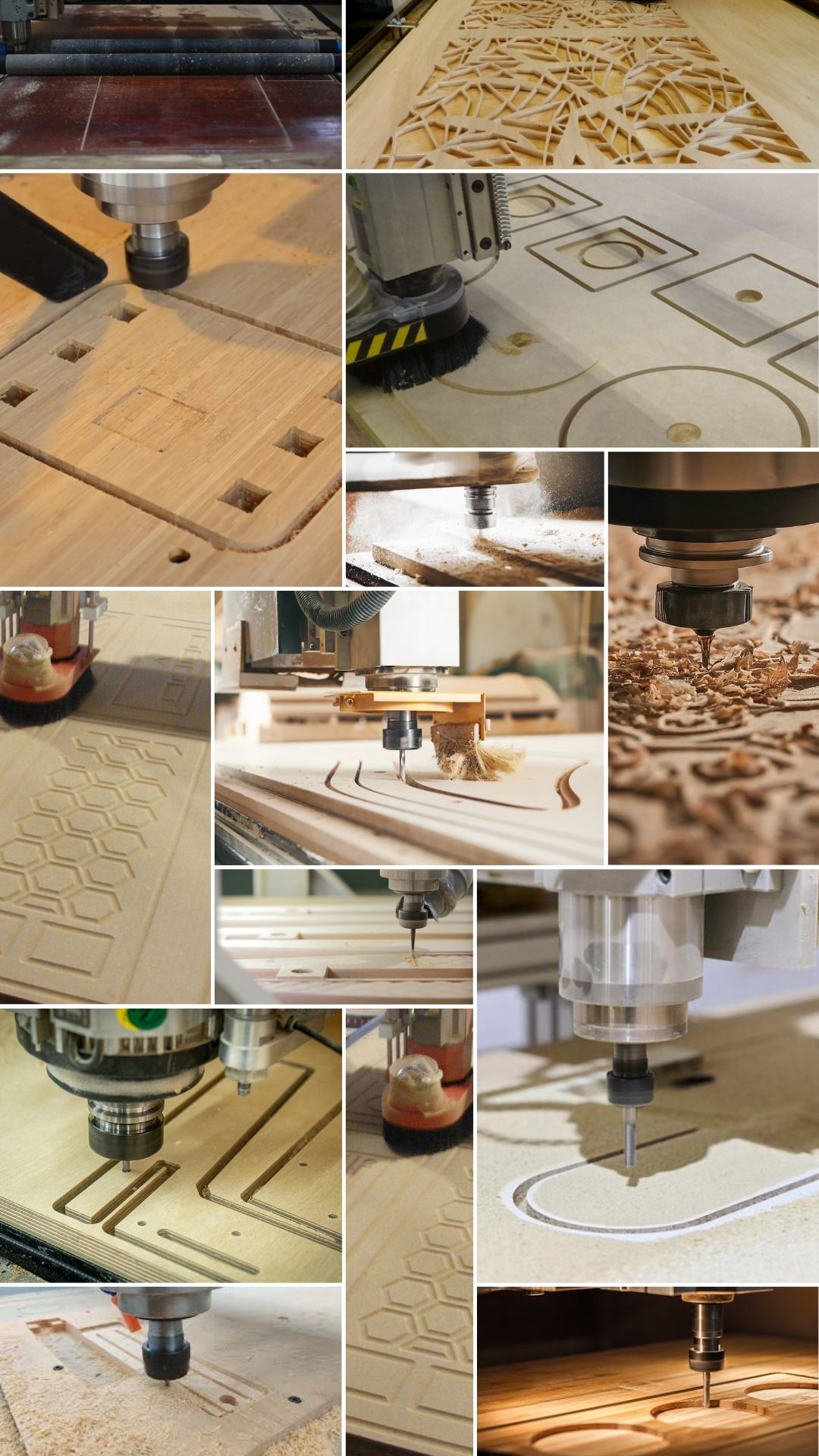

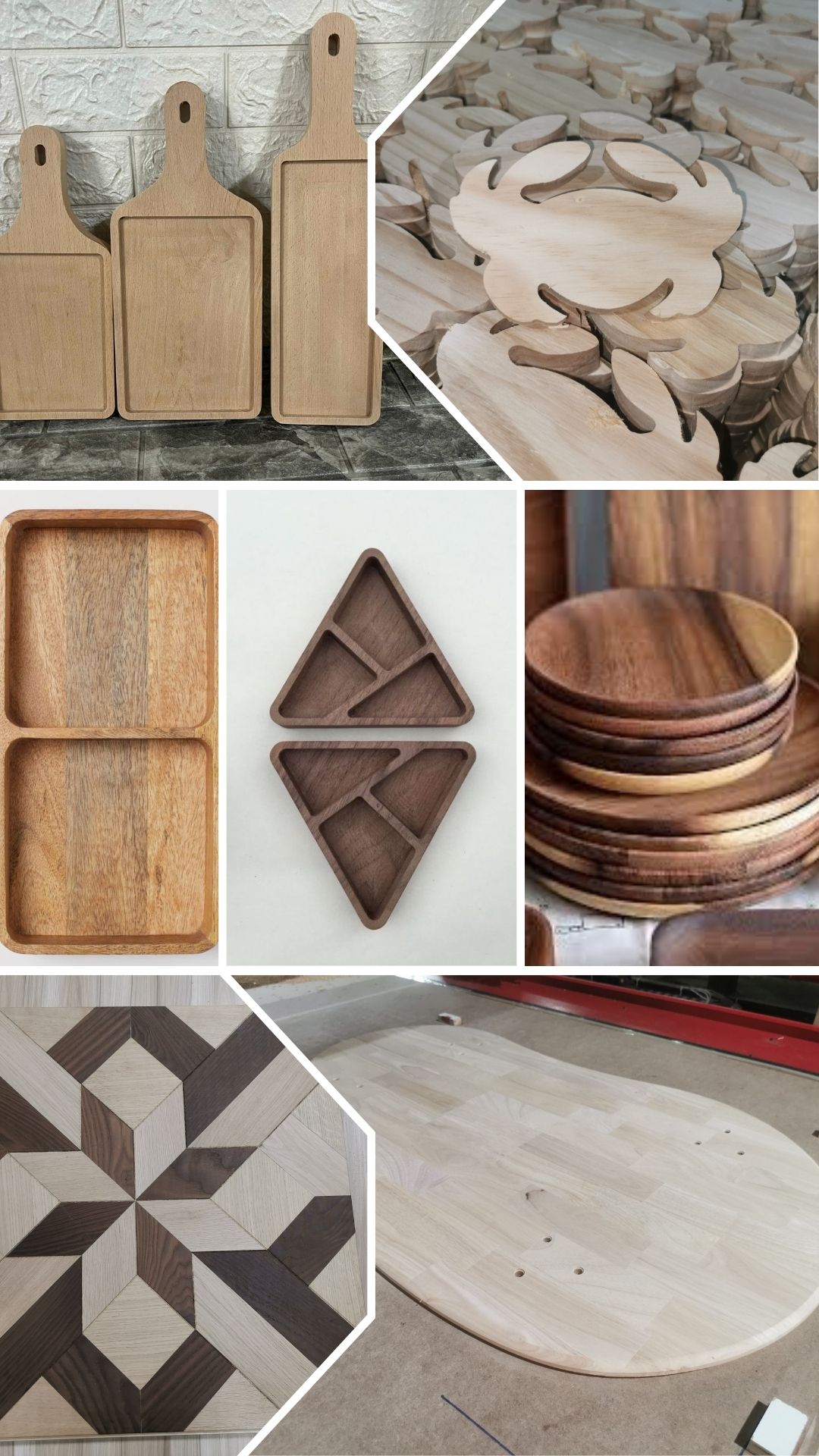

Dong Phuong Furniture Company (DPF) provides 2D CNC cutting services, ensuring the best product quality and fastest production time. We have a team of experienced technicians and are highly trained in CNC cutting technology, and we own the most modern equipment to meet the production needs of our customers.

Our bulk 2D CNC cutting service includes cutting and machining products from wood, sheet plastic, sheet metal, mica, cemboard, foam and many other materials. We specialize in CNC cutting according to customer requirements, ensuring high accuracy and fast production time.

With our experience and advanced techniques, we are committed to providing customers with the best products and services. If you are interested in any of our services, please contact us for detailed advice and quotes. We look forward to cooperating with customers to achieve their production and business goals.

We are committed to providing high quality services and meeting all customer requirements. We will always try to provide the most optimal solution for customers, helping to save production costs and ensure the best product quality.

Application process at Dong Phuong Furniture

1. Receiving requests

- Customers provide ideas, drawings or detailed descriptions of the desired products.

- Staff will discuss to clearly understand customer requirements and expectations.

2. Design consultation

- The professional team will advise on design, materials, colors and product finishing.

- Provides information about modern design trends and features of each material.

3. Sketch the design

- Based on requirements and consultation, the company will create initial design sketches.

- Customers will review and comment on these sketches.

4. Edit and perfect the design

- After receiving feedback from customers, the design team will make the necessary edits.

This process can be repeated many times until the customer is satisfied with the final design.

5. Confirm design

- Once the design has been completed, the customer will confirm and sign the contract.

- Information on prices, delivery times and other terms will be clearly defined.

6. Manufacturing

- The company begins the production process according to the approved design.

- Using modern technology to ensure high quality and accuracy.

7. Quality check

- Products will be thoroughly checked for quality before delivery.

- Ensure that products meet customer required standards.

8. Delivery

- Products will be delivered to customers on time as committed.

- The company will also support customers during the installation process if necessary.

9. After-sales service

- After delivery, the company will contact to ensure the customer is satisfied with the product.

- Support in handling arising problems, if any.